OUR

KNOW-HOW

(RE) DISCOVER

A LEGEND

Welcome to Ingrandes, France. Here, the expert hands of our 220 master bootmakers execute each stroke perfectly, rounding out the work of the machines. The rubber is shaped, the boot comes into being, and the legend continues -- begun in 1853, it has a long future ahead.

A LOCAL

PRODUCT

MADE HERE…

... and preserving local know-how. Aigle owns the only natural rubber boot manufacturing plant in France, in line with our commitments to sustainable and responsible fashion. These boots respect those who wear them and those who make them: they are certified of Guaranteed French Origin.

MANUAL

KNOW-HOW

ONE BOOT, 60 STEPS…

... And a meticulous inspection process, to ensure perfect sealing and flawless manufacturing. Once on your feet, they will serve you for years. Nothing is left to chance: it takes two years to become a bootmaker... learning techniques that have remained (almost) unchanged for 170 years.

CENTENNIAL

EXPERTISE

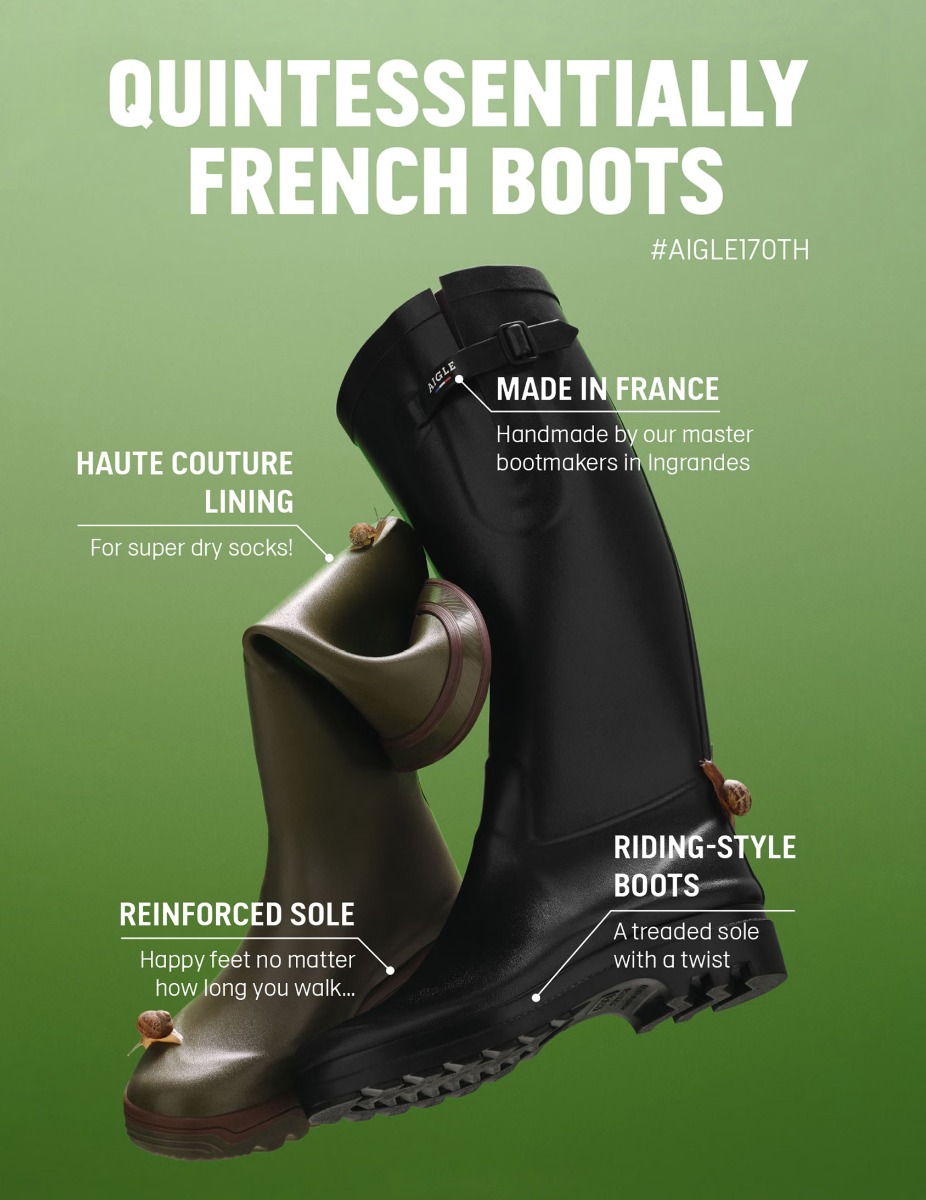

THE DETAILS THAT MAKE THE DIFFERENCE

THE SOLE

Notched or ultra-light, depending on what you wish to do

REINFORCEMENTS

Front and upper to resist wear and tear

ADJUSTABLE STRAP

To fit the width of your calf

A GUSSET

For more comfort on the leg

THE LINING

Warmer or cooler, depending on the season

THE MATERIAL

Natural and recycled rubber

A HISTORIC PATENT

A KEY STEP: VULCANISATION

From as early as the Great Discoveries of the 15th century, latex was used in South America to design certain everyday objects that could be almost waterproof.

The vulcanisation process would make it possible to transform rubber so that it could withstand variations in temperature without becoming brittle in cold or sticky in heat. In the 19th century, rubber became widely used to make tyres. Hiram Hutchinson, the founder of Aigle, acquired the patent, expressing his belief in the future of rubber shoes.